搜索此博客

2015年12月30日星期三

2015年12月27日星期日

2015年12月16日星期三

2015年11月29日星期日

2015年11月13日星期五

Pineapple slicer(slicing machine) by Bway

For fresh pineapple slices, frozen apple slices, preserved fruit slices, crisp chips, it’s vital to choose the slicing machine, which affects the crucial importance: product looks, thickness, use ratio and consumption of energy and etc.

The advantages of the fast slicing machine are fast, vertical slice, and round shape slices. The speed is 16pcs per second, loss is nearly zero. It also can slice dragon fruits, onions, lemons, pears, potatoes and more than

60kinds of fruits and vegetables.

The main material is stainless steel, the brand of PLC and touch screen is Omron. The fast slicing machine consists of 4pcs blades, feeder, output,3 layers security protection, control system and motors. The thickness and

speed can be adjusted. It can be cleaned by flushing. The fast slicing machine is safe, easy to handle and maintain,

and in line with the modern food safety and sanitation standard.

For operating, firstly set the thickness, match the size of feeder, and then put the peeled/cored apple into the feeders, press the bottom, finally the nice round slices would automatically come out.

|

| pineapple slicer |

2015年10月23日星期五

Apple slicing machine

Apple slicing machine can slice 10000pcs hour, nice shape, easy for making frozen apple slices, dry apple slices

2015年10月21日星期三

ginger peeling machine/ginger washing machine

ginger peeling machine/ginger washing machine

diamentionL 2450*1020*920,

Power 3KW,

Weight: 420kg

diamentionL 2450*1020*920,

Power 3KW,

Weight: 420kg

2015年10月16日星期五

Fast slicing machine(slicer) can slice apple ,slice lemon 1ton per hour

For fresh apple slices, frozen apple slices, preserved fruit slices,

crisp chips, it’s vital to choose the slicing machine, which affects the

crucial importance: product looks, thickness, use ratio and consumption of

energy and etc.

The advantages of the fast slicing machine are fast, vertical slice, and

round shape slices. The speed is 16pcs per second, loss is nearly zero. It also

can slice dragon fruits, onions, lemons, pears, potatoes and more than 60kinds

of fruits and vegetables.

The main material is stainless steel, the brand of PLC and touch screen

is Omron. The fast slicing machine consists of 4pcs blades, feeder, output,3

layers security protection, control system and motors. The thickness and speed

can be adjusted. It can be cleaned by flushing. The fast slicing machine is

safe, easy to handle and maintain, and in line with the modern food safety and

sanitation standard.

For operating, firstly set the thickness, match the size of feeder, and

then put the peeled/cored apple into the feeders, press the bottom, finally the

nice round slices would automatically come out.

Contact me for more details and video

2015年9月8日星期二

How to keep the peeled coconuts white color

You must encountered the peeled coconut turning brown after a while.It's the normal oxidation effect in most fruits and vegetables.

so is there any way to keep the white color? Yes,you can follow some easy steps below:

And for cut coconut to diamond shape, there is also a coconut cutting machine.

for more details, pls contact coconut cutting machine manufacturer.

2015年8月25日星期二

2015年8月23日星期日

2015年8月17日星期一

2015年8月6日星期四

coconut paring machine/coconut peeling machine remove coconut inner skin

coconut paring machine/coconut peeling machine remove coconut inner skin,Máquina de descascar coco

one hour can peel 300pcs, fast and easy.

For more info, pls refer to nellysun@gmail.com

2015年8月5日星期三

coconut deshelling machine ---the fast way to remove shell of coconuts

Are you still using knife to deshell the coconuts? it's very hard, and time-consuming, why not try the coconut deshelling machine, it would help a lot

2015年8月2日星期日

Automatic Butternut Squash Peeler

Butternut squash peeling machine, good helper to make squash soup.

Automatic Butternut Squash Peeler can peel 300-400pcs /hour, automatic suitable for the size of squash, thickness can be adjusted from 1 to 10mm

Bway--better way for life.

for more detail, refer to www.facebook.com/bwaypeeler

or email to nellysun@gmail.com

2015年7月30日星期四

How to peel the cantaloupe? Is there any machine?

Do you want a cantaloupe peeling machine? which can peel the skin in seconds

2015年7月27日星期一

Pineapple peeler pineapple cutter decore

Want to eat fresh pineapple, it won't be hard to eat

if you have a handy pineapple peeler, cutter, and core-remover

2015年7月15日星期三

coconut cutter machine ready to ship out

50pcs coconut cutter is ready to ship out

What are you waiting for?

Time waits for nobody

for more detail, refer to www.facebook.com/bwaypeeler

https://www.youtube.com/playlist?list=PLfEHgn9HuoP3ednIUuJjtOslkr5eOHEvE

http://bwaypeeler.blogspot.com/

2015年7月11日星期六

2015年7月6日星期一

Auto coconut cutter save your time and energy

Still using knife to cut the coconuts? you must sweat a lot, so try use the coconut cutter instead of labors, your time can be used on good things, such as having dinner with your wife, listening to your son singing, watching your daughter dancing.

2015年6月26日星期五

Bag filling machine for mineral water

Bag filling machine for mineral water, juice, jams,sauce, multi-uses, bags can be different volume, aluminium coating, or aluminium bag for different purposes.

Avocado pitting machine/remove avocado core

Avocado pitter can remove the core 40pcs/minutes, fast and easy, it would a great help for make avocado jam and avodado salad and more.

2015年6月24日星期三

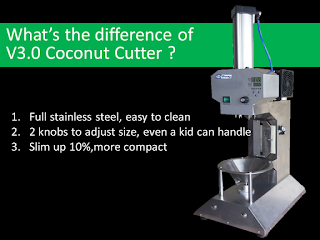

80% people are aware to use Auto coconut cutter, are you?

80% people are aware to use Auto coconut cutter, are you?

Coconut cutter is also called coconut trimming machine, coconut peeling machine, coconut peeler.

V3.0 updated to full stainless steel, knob adjusting size, easy to handle.

Coconut cutter is also called coconut trimming machine, coconut peeling machine, coconut peeler.

V3.0 updated to full stainless steel, knob adjusting size, easy to handle.

2015年6月21日星期日

Coconut water extractor

Tender Coconut Water Extractor is to cut coconut into halves to get juice inside, it's working fast, can be equipped to processing line.

capacity is to process 2500pcs coconuts per hour.

2015年6月17日星期三

How to cut coconut to diamond shape?Coconut peeling machine can do it

Coconut peeling machine, also called coconut trimming machine, coconut cutter can cut nice diamond shape coconut in the blink of eyes, as easy as Handel a washing machine.

| auto green coconut peeling machine |

Coconut trimming machine is also called máquina_peladora_de_coco, coconut striper,coconut shaving machine,coocnut scraper, coconut cutting machine,coconut paring machine, coconut peeler, coconut peeling machine

contact me for more details

How to peel Jackfruit? That's a question

Do you like to eat Jackfruits? It's really tough work to open it, and get the flesh out,now there is a jackfruit peeling machine to peel jackfruit, so you can more easy to get the flesh.

for more detail, refer to www.facebook.com/bwaypeeler

or email to nellysun@gmail.com

Jack fruit peeling machine, also can peel breadfruit, below refer to video:

for more detail, refer to www.facebook.com/bwaypeeler

or email to nellysun@gmail.com

2015年6月11日星期四

How to remove the fruit skin fast-for factory use

2 peelings machine can remove more than 20 kinds of fruits, try it on

Hot filling PET bottle blow moulding machine

How to make the juice bottle? You will see in the video.

6 cavities, there are 6 moulds, one time can make 6 pcs,

The blow moulding machine can make 3000pcs/h hot filling PET bottles.

6 cavities, there are 6 moulds, one time can make 6 pcs,

The blow moulding machine can make 3000pcs/h hot filling PET bottles.

2015年6月10日星期三

How to cut a diamond shape coconut? There are 3 ways to choose

Coconut water is very healthy,and easy to get in the markets. Do you know the coconut isn't born like a diamond shape which we saw in supermarket.

By brilliant people, there are 3 way to cut a green coconut into diamond shape now.

| manual coconut machine is slow |

| auto coconut trimming machine is fast and easy |

| Advantages of auto coconut trimming machine |

| Advantage of coconut trimming machine |

| comparison of coconut peeler |

How to set up a small-scale factory processing fruits and vegetables

From FAO advice, there are 6 things you must know:

Some time must thus be devoted to coordinate two aspects that are vital to the development of a project of this nature, namely costs and the quality of the infrastructure needed to achieve the established goals.

It must always be borne in mind that since the food to be processed is intended for human consumption, the infrastructure must meet several requirements. The basic general aspects of such requirements will be analyzed in this chapter.

The infrastructure comprises different aspects of a project's implementation. Issues like physical layout, basic services or installations and equipment must thus be taken into account.

Nevertheless, in the case of a cottage industry and a small industrial scale system alike, simplicity must never neglect the basic principles governing industrial health and hygiene, which must characterize a food production system.

One aspect that must be borne in mind relates to construction details, which determine a plant's capacity to meet two objectives: to adjust to the production of foods and to ensure a sufficiently long shelf life. However, when considering home or small-scale industrial processing facilities, the cost of construction is an important factor which must be taken into account.

The building materials must be as light as possible, easy to readapt and install, considering that often the system users develop the plan themselves, by means of self-construction methods.

Occasionally, small-scale industrial plants are equipped with a steam production system, which however is more seldom found in home-processing plants.

Even when a home-processing plant can operate without electrical power, it is better for this service to be available, essentially to facilitate the processes by means of small devices that were developed and that improve workers' performance, thus guaranteeing a greater uniformity of products.

The most common processes that apply to fruit are drying, preservation, pulp concentration, the manufacturing of juice, nectars and sweets, and concentrated pulp processing.

The difference essentially lies in the size and application of electrical and mechanized equipment of a greater unit capacity, probably characterized by a greater resistance and durability, but based on the same technological principles.

In the specific case of a semi-industrial plant, the pots will be replaced by steam kettles, heating will be provided by a steam-boiler, and a small press as well as an autoclave will be available. A list of additional equipment that must be installed in a small-scale industrial plant is provided below.

When considering the setting up of a fruit and vegetable processing plant, whether it be a cottage industry or a small industrial scale system, the first point to bear in mind is the infrastructure required to properly lodge all of the necessary equipment.

Some time must thus be devoted to coordinate two aspects that are vital to the development of a project of this nature, namely costs and the quality of the infrastructure needed to achieve the established goals.

It must always be borne in mind that since the food to be processed is intended for human consumption, the infrastructure must meet several requirements. The basic general aspects of such requirements will be analyzed in this chapter.

The infrastructure comprises different aspects of a project's implementation. Issues like physical layout, basic services or installations and equipment must thus be taken into account.

Physical layout

The physical layout of a plan of this nature may be very simple, as it refers to a basic production system, involving small volumes and simple products, from a technological point of view.Nevertheless, in the case of a cottage industry and a small industrial scale system alike, simplicity must never neglect the basic principles governing industrial health and hygiene, which must characterize a food production system.

Production sites

Several different processes take place on the site where the production activity is performed, from the reception and conservation of raw materials, to the storage of finished products.One aspect that must be borne in mind relates to construction details, which determine a plant's capacity to meet two objectives: to adjust to the production of foods and to ensure a sufficiently long shelf life. However, when considering home or small-scale industrial processing facilities, the cost of construction is an important factor which must be taken into account.

The building materials must be as light as possible, easy to readapt and install, considering that often the system users develop the plan themselves, by means of self-construction methods.

Basic installations or services

Three basic services are required for the operation of a system as the one in question: electrical power, drinking water and the disposal of waste waters.Occasionally, small-scale industrial plants are equipped with a steam production system, which however is more seldom found in home-processing plants.

Even when a home-processing plant can operate without electrical power, it is better for this service to be available, essentially to facilitate the processes by means of small devices that were developed and that improve workers' performance, thus guaranteeing a greater uniformity of products.

Basic facilities

A fruit and vegetable processing plant must be set up in such a way as to rely on a number of basic facilities, which are generally similar in home-processing and small-scale industrial systems. Figure 1 shows a small-scale industrial production system for the processing of fruits and vegetables.Equipment

Figures 2-4 and pictures 1-20 illustrate different implements and machines comprising the basic equipment required for the home processing of fruit and vegetables. Figure 2 shows a steam-powered heating system, figure 3 shows a press for the extraction of juice, and figure 4 shows a pulp removing machine.The most common processes that apply to fruit are drying, preservation, pulp concentration, the manufacturing of juice, nectars and sweets, and concentrated pulp processing.

Equipment for a small-scale industrial plant

When analyzing the equipment required by a small-scale industrial plant, it may be observed that there are no great differences in terms of basic principles.The difference essentially lies in the size and application of electrical and mechanized equipment of a greater unit capacity, probably characterized by a greater resistance and durability, but based on the same technological principles.

In the specific case of a semi-industrial plant, the pots will be replaced by steam kettles, heating will be provided by a steam-boiler, and a small press as well as an autoclave will be available. A list of additional equipment that must be installed in a small-scale industrial plant is provided below.

- - A small boiler producing 250 kilos of steam per hour.

- A vertical autoclave with a capacity for about 200-500 g jars.

- A pulper, which operates manually or electrically.

- A fruit peeling machine

- A fruit slicer

- A hand-operated hydraulic press.

- A pressure bottles closer.

- Two double-wall kettles.

our big dream -----One day can solve the problem for pre-processing 100kinds of fruits and vegs

Our big dream of Bway -----

One day we can solve the problem for pre-processing 100kinds of fruits and vegs, including fruit peeling machine, pitter, pitting machine, decoring machine, seeds removing machines, which mostly processed by manually.

We are keeping working on it. Now we can process around kinds of fruits and vegetables.

for more detail, refer to www.facebook.com/bwaypeeler

or email to nellysun@gmail.com

One day we can solve the problem for pre-processing 100kinds of fruits and vegs, including fruit peeling machine, pitter, pitting machine, decoring machine, seeds removing machines, which mostly processed by manually.

We are keeping working on it. Now we can process around kinds of fruits and vegetables.

for more detail, refer to www.facebook.com/bwaypeeler

or email to nellysun@gmail.com

mango peeling machine --Amazing

Mango peeling machine can automatically peel different shape of mangoes,even the ripe mango. if the mango Dia 40-100mm, Height 40-120mm.

It can peel 13-20pcs/minute,thickness can be adjust from 1-5mm.

Auto Mango peeler can replace 20 labors, it's great to make mango slice, mango jam and etc.

Look the peeled mango, want to eat right now

Bway--better way for life.

for more detail, refer to www.facebook.com/bwaypeeler

or email to nellysun@gmail.com

订阅:

评论 (Atom)